21 September 2022, Mumbai:

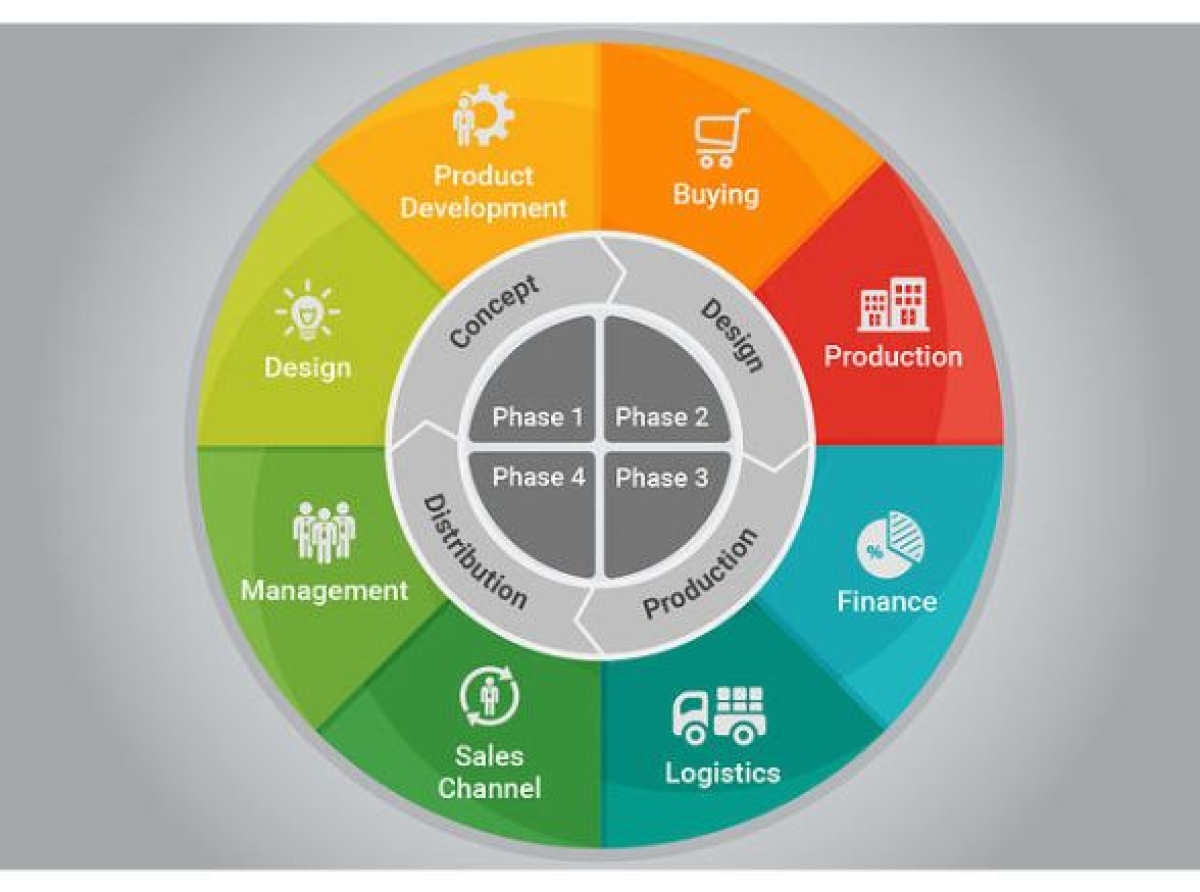

The product life cycle broadly is a period through the process over which any product per se gets to develop, introduced/placed to the marketplace, and subsequently needs to be withdrawn from the market. Increasingly it been witnessed that it is started to adopt IOTs, Algorithmic mapping as we move ahead. As per the copybook style, It typically has four pieces of this lifecycle: introduction, growth, maturity, and decline so to say.

Production

It is explainable that why firms need to improve the way they manage their product development both pre & post-production? PLM systems are very handy & meaningful for (T&C) textile and apparel manufacturers as this is one customer-facing industry in the changing paradigm needing a faster turnaround while responding to evolving fashion trends. Also as a use case aligns with vendors & long global supply chains while staying lean & mean.

Capacity

Capacity building for any manufacturing driven organisation is always regarded as a key pillar of product management. There is no hyper leverage setting the boundaries for the demand any organisation wants to cater to & the growth headroom the sector enjoys.

Planning

After all, the world is today's tech oyster in more than one way. More & more players are realizing the vitality of Multi-Modal Optimization appreciating enterprise comprehensive solution systems with problem-solving approaches starting to unfold as we usher in the digitized world.

Make no mistake PLM systems are mindfully focused, measurable; As most of businesses scientifically underpin plan & design to run their course.

Automation-Based Production Planning

Let us dwell on the WHY of Automated production planning. It is a forward-looking statement for any manufacturing system that employs tools like sophisticated digital/modern technology facilitating achieve curated planning, and speed to market in the VUCA (Volatility, Uncertainty, Complexity, and Ambiguity) world where no can insulate itself.

Vendor Outsourcing

How markets read this business aspect is that it is a credible discovery mechanism to hiring FTE; a business practice to do something alternatively with contracting outside the business players & making them undertake functions conventionally one would have hitherto performed in-house/within the premises. So to say this is a process phenomenon looking into the outsourcing strategy & in effect supporting to control business processes effectively for businesses facing supply chain headwinds as markets move on.

Total Quality Management (TQM)

The adage goes," Quality is never an accident". The actionable point here is that there is no better way to be in a mission mode than getting into the ongoing practice & process of overseeing the desired quality accomplishing precision, constantly delivering quality in the market by making small to midterm planning rather than longterm so as not to have a lot on the hands thus maintaining sound business balancesheets. Suffice to say at the end of the day one would argue that to meet aspirational quality management vision one has to streamline & align with the supply chains.

Workforce skill matrix

Popularly known as skill mapping across the workforce. In effect, this kind of matrix is an architecture meant to measure/take a stock of human resource capital any organization possesses and map workforce skills and their abilities & capacities in the run-up to building corporate capabilities.

Cost-Benefit Analysis

Most simplistically it is the gauge evaluating desired Key Performance Indicators (KPIs) in any manufacturing process/journey: across metrics like visible gains, deducting all costs, attributable to net profit and so & so forth. This syndrome is more a discoverability revealing that there is a palpable cut down in energy and environmental costs than ever before.

Impact Factor

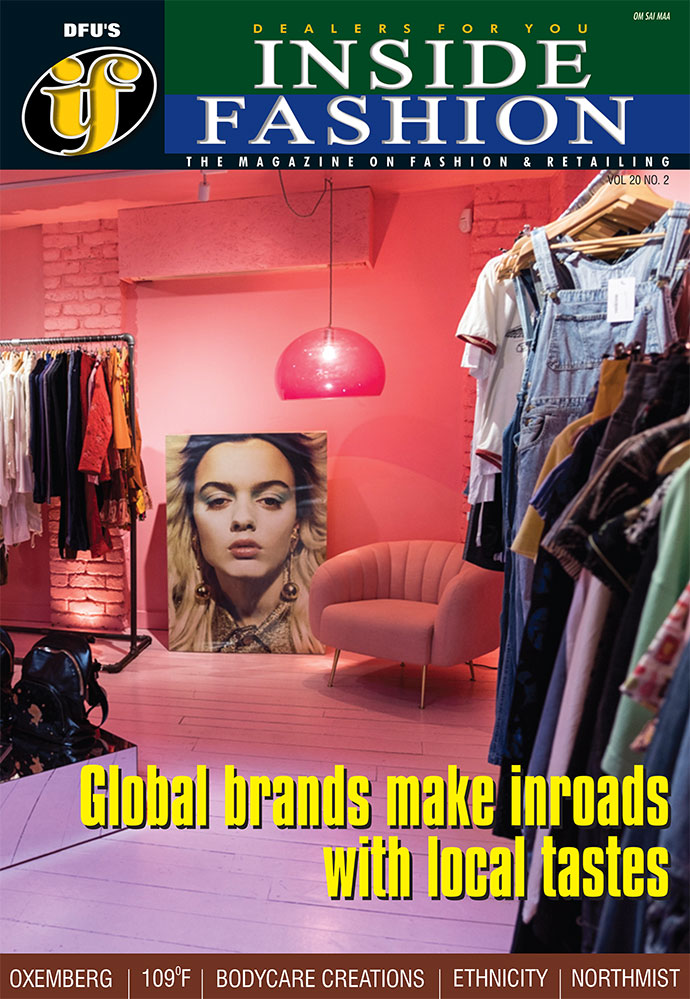

How useful Product life cycle management (PLM) is for textile and apparel (T&C) producers? Let us over here explore the options industry already has on its hands such as software companies with offerings from specialized PLM packages designed, and curated to meet the textile and clothing/apparel (T&A) sector viz Lawson and Lectra besides smaller software suppliers namely Yunique and DeSL.

As a case study Gini & Jony, India-Popular childrenswear brand in one of the industry studies comes in with a big revelation," PLM system has gainfully allowed cutting on production turnaround period helping constructively focus on creativity & designing the core to the brand's USP & philosophy.

Takeaways

As we remain vulnerable to the falling quality lest there is a formal management framework based on the business philosophy & deep trust that any entity can build attaining enduring success & be battle ready.

The article has dived into taking a sneak-peek in its entirety around the 'Lifecycle of Apparel Production' arguably in a very Reader-Friendly fashion to pack a punch.