21 July 2022, Mumbai:

“Way forward for Indian textile sector is companies are required to go vertical augmenting scope & scale by foraying into apparel manufacturing plants/value addition if Indian textile sector were to raise its market share in the global textile trade deeply integrating into supply chains”, Mr Sanjay Lalbhai, doyen of the Indian textile industry and CMD of Arvind Ltd informed delegates at one of the conferences.

From fibre, yarn, and fabric to garments, India's textile and apparel industry has strengths along the whole value chain. The traditional handloom, handicrafts, wool, and silk items, as well as the organised textile industry in India, constitute a large portion of the widely diversified Indian textile and apparel market.

The organised textile sector in India, which encompasses spinning, weaving, processing, and garment production, is characterised by the employment of capital-intensive equipment for the mass production of textile items.

ALSO READ Indian Textile Industry: Challenges & Opportunities

_large.jpeg)

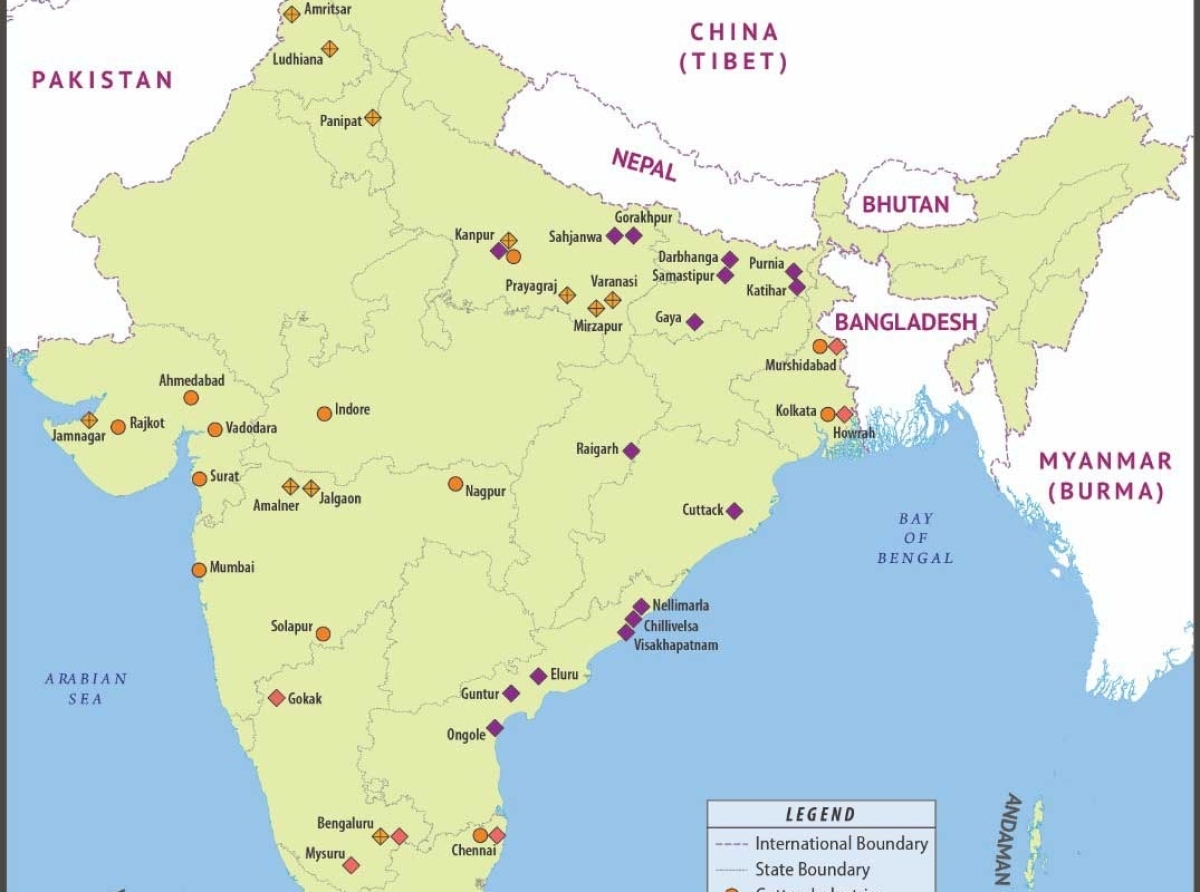

From April 2016 to March 2021, Italy, Japan, Mauritius, and Belgium will have contributed the most foreign direct investment (FDI) to India's textile industry (including dyed and printed textiles).

India's textile and apparel (T&A) exports, which include handicrafts, reached a record high of $44.4 billion in FY 2021–22, a significant rise of 41% and 26% over the corresponding amounts in FY 2020–21 and FY 2019–20, respectively. 40–50 million workers in related industries as well as 5.8 million farmers depend on cotton cultivation.

Additionally, the $75 billion in domestic consumption was broken down into $55 billion for garments, $15 billion for technical textiles, and $5 billion for home goods.

ALSO READ Anti-China Sentiments: Indian Textile Sector Is In A Sweat-spot

While exports included $12 billion in garment exports, $4.8 billion in home textile exports, $4 billion in fabric exports, $3.8 billion in yarn exports, $1.8 billion in fibre exports, and $2 billion in other exports.

RELEVANT NEWS How Much Is Depreciated Currency Supporting the Indian Textiles Sector

The Production-Linked Incentive (PLI) Scheme in Textile Products for Improving India's Manufacturing Capabilities and Improving Exports - Atmanirbhar Bharat - has received approval from the Union Cabinet, which is presided over by Prime Minister Shri Narendra Modi.

1. Out of 67 applications filed, 61 applicants have been granted approval under the Production Linked Incentive (PLI) Scheme for Textiles.

2. The government eliminates the import tax on cotton.

3. The programme consists of two parts. Part 1 requires a minimum investment of INR 300 crore and a minimum turnover of INR 600 crore to qualify for an incentive. Part 2 requires a minimum investment of INR 100 crore and a minimum turnover of INR 200 crore to qualify for an incentive.

RELEVANT NEWS Vietnam To India: How Can the Indian Textile Sector Benefit

It makes sense that Vietnam and Bangladesh, which export more textiles than China alone, are third and fifth, respectively, in the current World Trade Organization data assessment. India's exports have decreased 20% from 2016–17, reaching $29 billion in 2020–21, according to the Ministry of Commerce.

According to Wazir Advisors, the domestic market has decreased 30% in the last year, to $75 billion in 2020–2021; the firm predicts that the market will increase to $190 billion in 2025–2026.

RELEVANT NEWS Srilanka Economic Crisis & Its Favourable Impact On the Indian Textile Sector

Growth is essential since the textile industry employs about 45 million people and provides between 2 and 3 percent of India's GDP, 7 percent of industrial output, and 12 percent of export revenues.

RELEVANT NEWS 6. How Favourable Is Rupee's Precipitous Fall For Indian Textile Sector

In order to support its growth, the government unveiled a Rs 10,683 crore production-linked incentive scheme in September. Its goal is to boost the production of technical textiles, which are used to create items like sportswear, fishing nets, and disposable medical equipment.

Manufacturers have the option of investing either at least Rs 100 crore or at least Rs 300 crore and achieving a turnover that is at least twice as large comparisons.

A quick comparison with competing global apparel manufacturers in the developing world mirrors that the problem is quintessential to our internal conditions and then external factors.

This “shrinking global trade” argument has been made many times before too as an excuse for justifying India’s Textile trade & commerce below par performance in the exports.

Join our community on Linkedin