08 February 2023, Mumbai

The Hong Kong-based EPIC Group, established in 1984, is one clothing manufacturing company that has consistently gained recognition from the world's apparel sector.

The EPIC Group is adamant that providing full-service client solutions including design, product development, sustainability, innovation in products and processes, and order fulfillment—is more critical than merely producing goods.

Recently, Team Apparel Resources (AR) met with Roger Guy Young, Chief Strategy Officer, and Ranjan Mahtani, Executive Chairman of the EPIC Group in Dhaka. Our team had a frank conversation with Ranjan and Roger about how EPIC Group is operating differently to be able to support its objectives and carry out its ambitious ambitions throughout the meeting.

Within the previous three years, the sector has seen enormous upheaval. We all agree that during Covid-19, things were horrible for everyone in the business, not just us.

However, following the epidemic, things improved very rapidly. After a slowdown in 2020 and early 2021, consumers were back on the streets. They chose to engage in "revenge shopping," and retailers strengthened their purchasing power. The garment manufacturing business benefited significantly from these initiatives, and we were no exception.

The client demands and their expectations

The procedure for fulfilling client orders is evolving, another development we are now seeing. We have warehouses in the USA, but we only transport some of our shipments; instead, we build, ship, and distribute directly to retail locations. By doing this, we significantly increase supply chain speed and efficiency to satisfy customer needs, much as a domestic brand or retailer would.

Young people purchase in many new ways; thus, all supply chain participants must be prepared for these shifting purchasing habits. However, just when we believed the pandemic's problems were behind us, we faced new problems due to the crisis in Ukraine, the economic downturn, and record prices in specific key shopping locations. We have built a very resilient organization and business model, and since we believe it is all now just part of doing business, we are prepared to respond to change in the world with incredible speed.

Our continued priority is keeping our top line steady. Fortunately, our company has a low debt-to-equity ratio and a sizable cash reserve, which is essential for running a business, especially in these uncertain times.

Owner of Parimala, Lady Tailoring Classes G. Kousar stated, "I have been in the tailoring industry for seven to eight years. Previously, each batch had six participants who attended the classes; currently, there are just three.

In addition to teaching stitching, I also sew garments and profit from that venture. Due to the epidemic, my consumer base has been cut in half, and most of my purchases come from family and friends. The majority of Indians relied on neighborhood tailors up until the late 1990s.

Due to a lack of size standardization, few ready-to-wear clothing alternatives were available to the public. A 2014 research by the India Retailing Bureau found that consumers are increasingly choosing ready-to-stitch (RTS) fabric and customizing their clothing to fit them.

"During the holiday season, I made a significant amount of money, but now that the virus has spread, fewer people are celebrating holidays, so my business has entirely dried up. I make between Rs 10,000 and 20,000 per month. Managing all the household bills today is quite complex”, she continued.

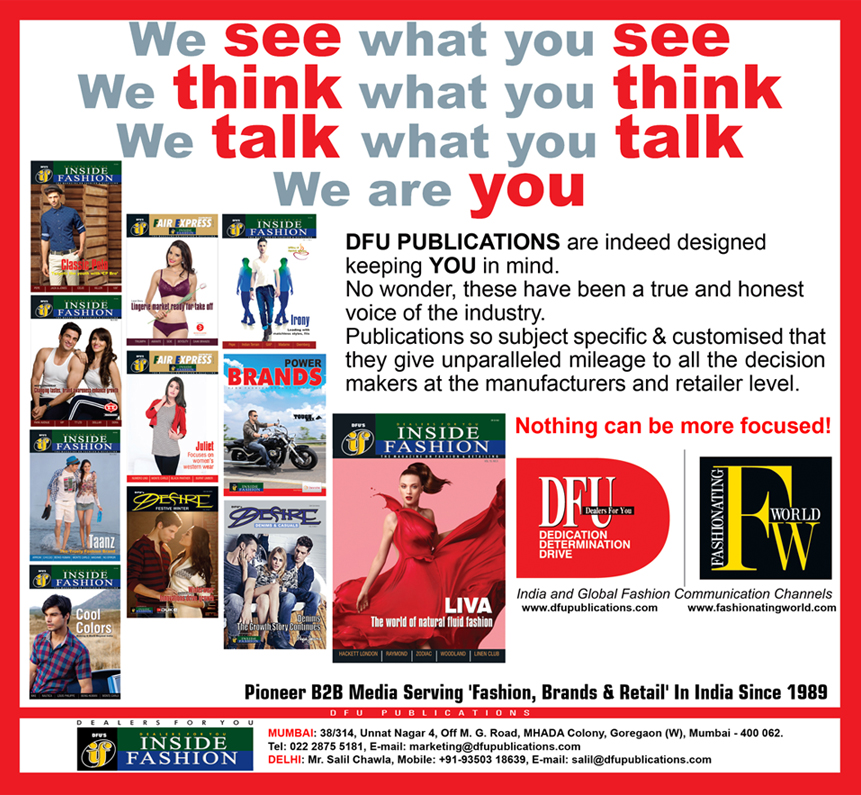

Latest Publications