06 December 2022, Mumbai

We are all more connected than ever to one another today. Mobile devices, sensor technology, and digital networking have made this all possible. Future smart factories are becoming a reality thanks to these technologies where key trending issues have been penciled in simply are efficiency, innovation, and enterprises’ digitalization marching sector to the future.

Realizing that there is a palpable keenness being witnessed across sectors and how the apparel sector can be any different in its tryst with the experimentation/chancing upon emerging technologies leading to a great technology demand waiting on the sidelines and subsequent follow-up evaluation affecting the real business processes operationally.

Orderly evolution

The sustained quest of the industrial world to promote smart manufacturing to digitalize conventional/archaic manufacturing processes has led to orderly evolution through industrialization in the 19th and 20th centuries.

The four stages of the industrial revolution are as follows. Utilizing water and steam to speed up mechanized production was the first revolution. The vast output of electricity constituted the second revolution. The third revolution saw the development of information technology powered by electronics, such as telecommunications and microprocessing. Finally, we are in the fourth revolution, where information technology and electronics combine physical, digital, and organic aspects of contemporary human life to enable complete digital connectedness.

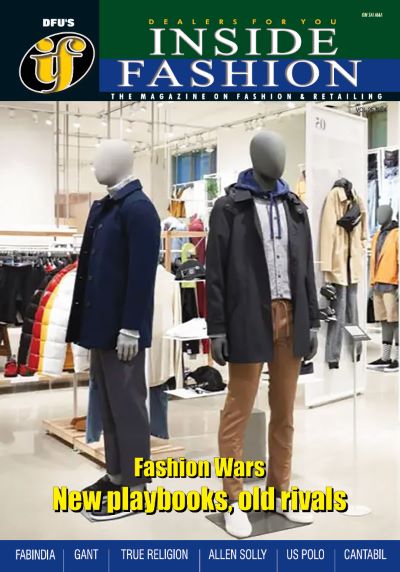

How future Factories might look

Future factories will be fully automated, self-maintaining, and self-repairing buildings with minimum human involvement. The quick development of these technologies is helping to introduce new processes and optimize the ones that are already in place.

Mass customization is made possible by an apparel smart factory by reconfiguring the production workflow to be more flexible, modular, and economical. Robotics, artificial intelligence (AI), the internet of things (IoT), and analytics are all used in smart manufacturing.

Furthermore, these technologies enable the factory's operations to operate autonomously with minimal human involvement, learn in real-time, and adapt. Employees can concentrate on higher-level decision-making duties once factories are able to perform the mundane chores.

Tailor-made solutions

A tailor is needed to make clothing specifically for a person. However, store managers, designers, and developers may work together in real-time thanks to the Internet of Things. It aids them in providing a product tailored to a customer. It is also possible to complete the operation without disrupting the entire supply chain.

Boston's Ministry of Supply manufactures blazers, shirts, skirts, and sweaters that customers design themselves using thermal imaging, 3D printing, and 3D knitting technology. These goods don't create any material waste and are additionally tailored to the heat mechanics of the user.

Microfactories; For an automated on-demand apparel factory to handle personalized orders with just one click of the mouse in the future, Amazon submitted a patent in 2017. In order to design such a system, a variety of technologies are needed, including augmented reality and computer vision for design and fitting, 3D printing for manufacturing, computer vision and artificial intelligence for shop floor operations, machine learning for logistics, and robotics for packaging and distribution.

Next Factory of the Future

The shop floor production procedures of clothing/apparel manufacturers are being automated with the aid of CGS Innovations. On a variety of materials, RFID tags are being used to automatically change the sewing machines' settings. Therefore, engineers can easily alter the settings on every machine on the shop floor, reduce expenses, and boost production using digital automation. The fourth revolution is the most important one for the apparel/garment, fashion, and footwear industries since smart factories are popular.

The background of the presently prevailing worldwide economic meltdown and so-called impending recession is mounting up pressure on an already battered manufacturing industry on account of back to the back pandemics of healthcare & Russia's war on Ukraine setbacks underlines particularly the need to ratchet up flexibility and efficiency of production processes to weather the economic tsunami/downturn.

Therefore, the unfolding dynamic scenario of the 'smart factory' manifests the height of this development Integrated user interfaces, let us make no mistakes will still be much-needed requisition at any/most of the factories for fundamental core functionalities.

Where is this taking us?

The fashion and apparel/garment business can communicate with their clients in real-time and provide them with what they need thanks to the industrial revolution, which is unstoppable as it makes use of the factories of the future. We are getting closer to creating the factories of the future as more and more manufacturing equipment and parts integrate sensors and automation technologies and also integrate the core characteristics of this dynamic evolving smart manufacturing concept to the existing mundane production/manufacturing practice/s.

Future factories will utilize systems that are improving, becoming more affordable, and becoming quicker. As a result, these systems are committed to improving the productivity, efficiency, and competitiveness of the manufacture and production of apparel/clothes.

The article is a quest reporting foundational blocks with regard to the fundamental core technologies required to develop the future-generation factories and emerging new kids on the block.

What portends future trending is in general to manufacturing and in particular to the fashion industry which can not be an outlier when the comparison between Digital Factory, Virtual Factory, Smart Manufacturing, and Cloud Manufacturing is fast becoming a prime mover in a digital world.

Latest Publications