10 March 2022, Mumbai:

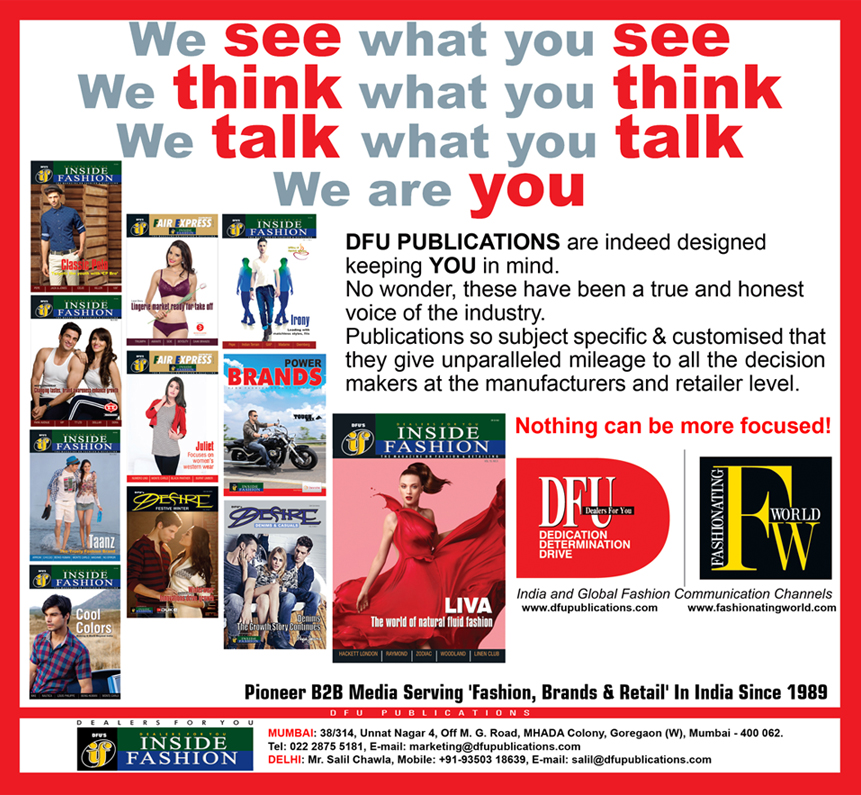

Thanks to its strategic focus on wood-based specialty fibers and the predominantly positive market environment, the Lenzing Group recorded a significantly improved revenue and earnings performance in 2021 compared to the previous year.

Increasing optimism in the textile and apparel industry as a consequence of the progress made with vaccinations and the continuing recovery in the retail sector ensured a strong rise in demand and prices on the global fiber market, particularly at the beginning of the reporting year.

Revenue grew by 34.4 percent to EUR 2.19 bn. In addition to the predominantly positive market environment, the focus on specialty fibers such as TENCELTM, LENZINGTM ECOVEROTM and VEOCELTM branded fibers also had a positive impact on revenue growth.

ALSO READ: Lenzing AG: Stephan Sielaff, new CEO

Specialty fibers currently account for 72.3 percent of fiber revenues. Significant increases in energy, raw material, and logistics costs occurred throughout the reporting year.

Earnings before interest, tax, depreciation, and amortization (EBITDA) almost doubled compared to the previous year to reach a level of EUR 362.9 mn (after EUR 192.3 mn in 2020).

The EBITDA margin rose from 11.8 percent to 16.5 percent. Net profit for the year amounted to EUR 127.7 mn (after EUR minus 10.6 mn in 2020), and earnings per share stood at EUR 4.16 (after EUR 0.24 in 2020).

“Lenzing can be pleased with a strong business year. Demand for our wood-based, biodegradable specialty fibers under the TENCELTM, LENZINGTM ECOVEROTM, and VEOCELTM brands continued to perform very well in 2021,” notes Cord Prinzhorn, Chief Executive Officer of Lenzing Group.

RELATED ARTICLE Lenzing: Comes up with global lyocell facility

Join our community on Linkedin

_large.jpeg)

_large.jpeg)

_large.jpg)

_large.jpeg)